Are you being undermined by "cost assassins" in your manufacturing operations?The grinding of a single PCD tool could be "grinding away" your profits as well. The three major "cost assassins" in PCD tool processing—annual consumption of copper electrode consumables, hidden costs of manual monitoring, and losses from high scrap rates—are eroding your margins bit by bit. When urgent orders come in, does your tool grinding workshop become a "bottleneck"? Forced to extend delivery cycles? Watching market opportunities slip away?

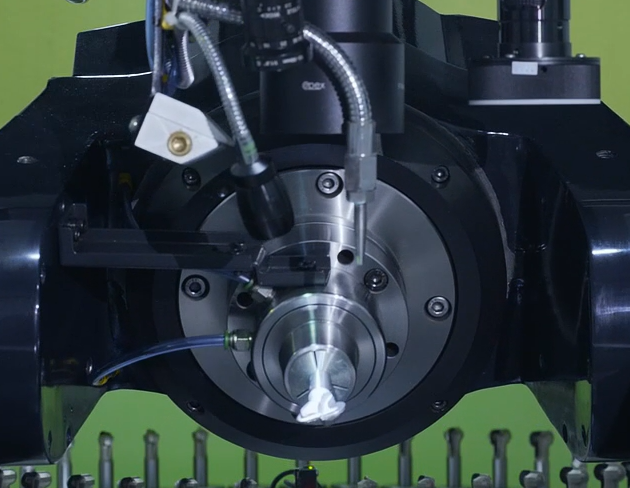

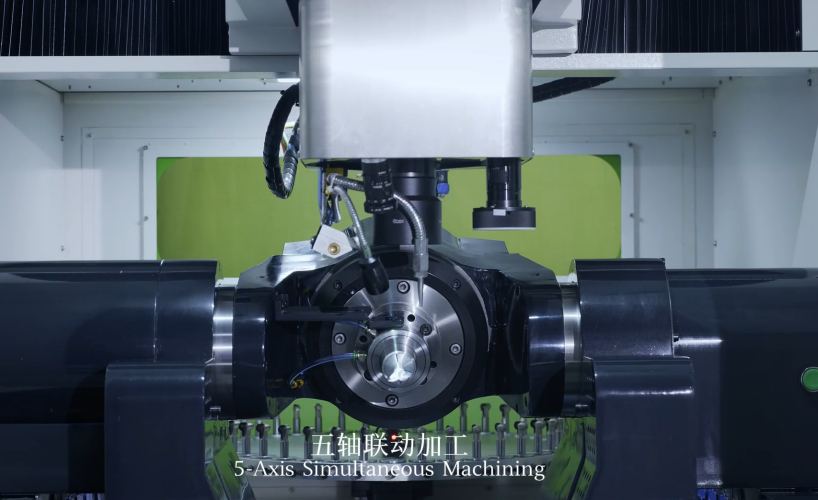

Now, the game-changer is here. As a professional 5-axis laser tool processing machine, the Novick CL2-400 adopts 5-axis simultaneous laser cutting technology with "zero consumables and high efficiency." It eliminates copper electrode wear, manual dependency, and unstable precision, enabling a leap from "barely keeping up" to "leading the entire way" in manufacturing fields such as woodworking, automotive, and aerospace.

Technological Breakthrough | Synergy of Mechanics & Electronics, Integration of Precision & Stability

Mechanical structure is the foundation of precision. The CL2-400 features a high-strength cast iron bed, providing excellent damping performance and thermal stability to maintain consistent precision during continuous operation. Its dual-supported cradle-type rotary axes ensure long-term rotational accuracy; the A/B axes utilize DD motors paired with absolute encoders, eliminating backlash from mechanical transmission and achieving a positioning accuracy of ±2 arcseconds.

Electrical structure is the guarantee of stability. The CL2-400 adopts a modular electrical cabinet layout and design, which is not only sleek and tidy but also offers outstanding anti-interference capabilities. Comprehensive protection functions and safety interlock mechanisms ensure all-round safety; a stable power supply system combined with remote diagnosis and maintenance functions significantly reduces equipment downtime, keeping production running smoothly.

Intelligent Evolution | Tackle Complex Processing with Ease

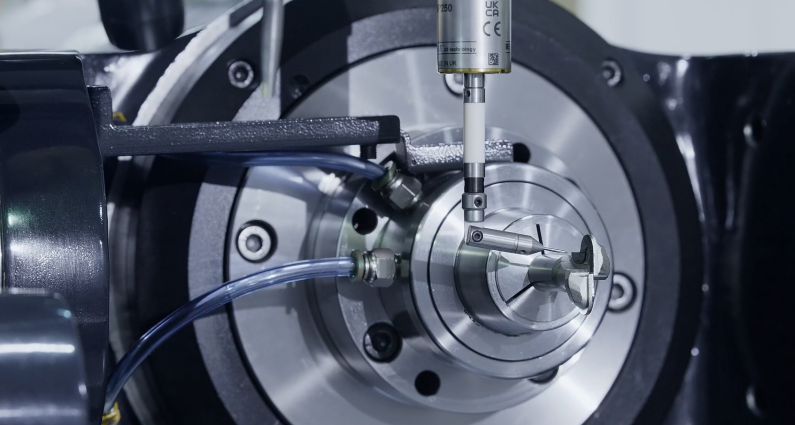

What is the core competitiveness in the era of smart manufacturing? User-friendliness and efficiency! The CL2-400's intelligent design allows novices to master operations quickly. It comes with a built-in professional tool intelligent management system, preloaded with 8 tool process libraries covering typical tool types such as regular reamers, step reamers, inner sleeve tools, and thread tools. One-click selection enables rapid setup of processing parameters, greatly improving operational efficiency.

User-friendly HMI & convenient operation! Powered by the Windows 10 system and modular software architecture, it features integrated live video monitoring of the operation process with a visual interface. Programming can be completed by dragging graphics or importing CAD models, significantly reducing learning costs.

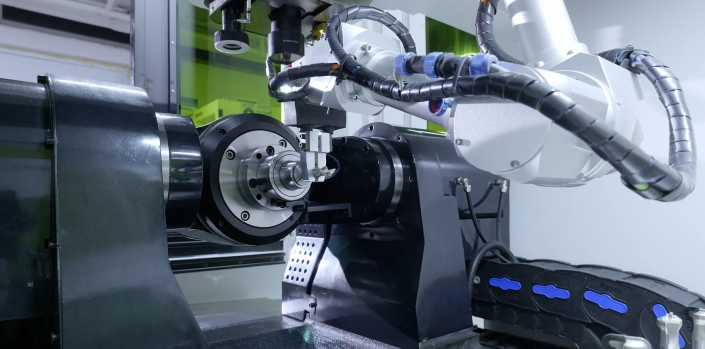

Additionally, the CL2-400 boasts high-speed 5-axis synchronized motion and dynamic precision control, dynamic precision, reliable system performance, platform scalability, processing path planning, path simulation and error correction, integrated system synergy, ease of use, and remote diagnosis and digital functions. It delivers an intelligent processing experience of "set and produce," supporting continuous production.

Outstanding Performance | High Parameters, Wide Adaptability, Easy Mastery Across Industries

Powerful parameters enable versatile applications. Is the CL2-400 truly a versatile "intelligent manufacturing solution"?

Absolutely!

Superior parameter configuration: The CL2-400 offers X/Y/Z axis strokes of 300×400×300mm, an A-axis rotation angle of -210°/+40°, and a B-axis rotation of ±360°. The bidirectional positioning accuracy is ±0.003mm, and the unidirectional repeat positioning accuracy is ±0.001mm for the X, Y, and Z axes. It perfectly meets the high-precision processing requirements of complex tool types, laying a solid foundation for product quality.

Wide application scenarios: From woodworking to aerospace, the CL2-400 handles complex tool types in one stop. Typical tools include woodworking cutting tools, edge banding tools, automotive reamers, and step tools; applicable industries cover furniture manufacturing, auto parts, molds, aerospace, etc. Equipped with fully enclosed protection and dust collection functions, the CL2-400 balances safety and environmental protection.

Value Verification | More Than a Machine, A "Profit Accelerator"

Choosing the CL2-400 is not just buying a machine—it's introducing a "profit growth system" to your enterprise!

① Efficiency improvement: Laser cutting speed far exceeds traditional grinding. Combined with automatic tool changing and an intelligent process library, it enables unattended processing, put an end to delivery date anxieties. ② Cost savings: Laser processing requires no consumables such as copper electrodes, with low energy consumption and minimal maintenance, significantly reducing total cost of ownership. ③ Quality assurance: High-precision positioning and stable performance ensure strong tool consistency and low defect rates, while supporting customized processing. ④ Technological substitution: The CL2-400 will gradually replace traditional grinding and EDM methods, empowering advanced productivity.

These values are not just a stack of technologies—they embody Novick's corporate mission: to make machines intelligent partners that create value for customers. We understand that an excellent machine must not only have leading parameters but also seamlessly integrate into customers' production processes and solve real pain points. Therefore, every design detail of the CL2-400 reflects Novick's R&D philosophy of "mastering core technologies and focusing on customer experience."

Based on this philosophy, Novick has always focused on the high-end CNC equipment field, providing customers with optimal solutions. Since its establishment in 2002, Novick has accumulated nearly 100 patents and software copyrights, investing approximately 10% of its annual revenue in R&D. It has grown into a globally influential manufacturer of electrical processing equipment, with products exported to more than 20 countries and regions including South America, North America, Europe, and Southeast Asia. We firmly believe that true service begins before equipment delivery and is rooted in R&D and design. Therefore, we adhere to the principle of "customer first, service-oriented," providing comprehensive technical support to ensure worry-free production for our customers.

Now is the time to upgrade your tool machine.

While some are still struggling with copper electrode wear and precision woes, others have already embraced unmanned, consumable-free, high-precision smart manufacturing with the CL2-400.Designed exclusively for PCD superhard tools, the CL2-400 turns efficiency improvement, cost reduction, and value enhancement from slogans into tangible profits!

Novick Service Hotline:+86-316-5922666

Official Website: https://www.en.novick.cn/

WeChat Official Account: Novick (安德建奇)

© ไทยนิวส์เอ็กซ์เพรส